Non-destructive X-ray diffraction equipment that can be used anywhere by anyone.

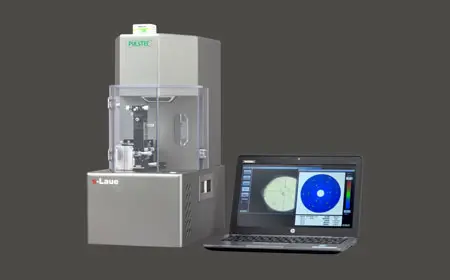

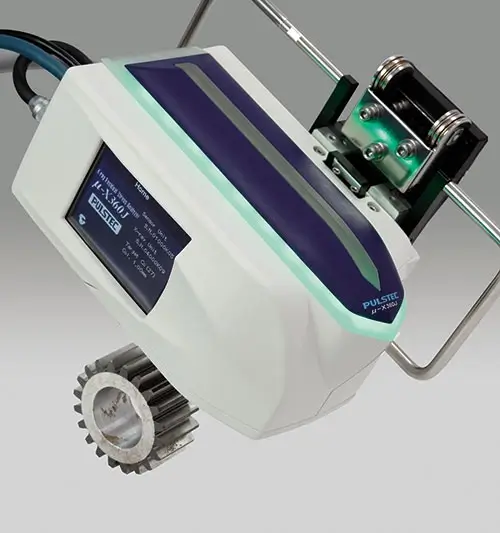

Founded in 1967, Pulstec manufactures innovative, non-destructive equipment for industrial and research and development applications. Our versatile product line, ranging from our legacy μ-X360J to our s-Laue and m-Laue systems, is designed to provide repeatable and accurate residual stress measurements, crystallinity evaluations, case depth hardness assessments, and more.