Flexible for Large Samples & Integrated Systems

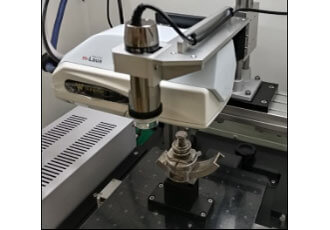

m-Laue Flexible Single Crystal Orientation System

Flexible for Large Samples & Integrated Systems

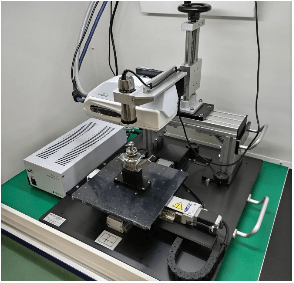

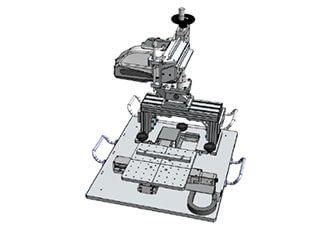

Pulstec’s inline single crystal orientation can be configured for on-site and lab use. Similar to our original s-Laue model, the m-Laue is intuitive. It only takes three simple steps to determine single crystal orientation:

Note: External stage (θ,χ,ψ, and z) is required; shielding plan is required

With the motorized XY slide stage, you can perform orientation mapping within a 150 x 150mm area.

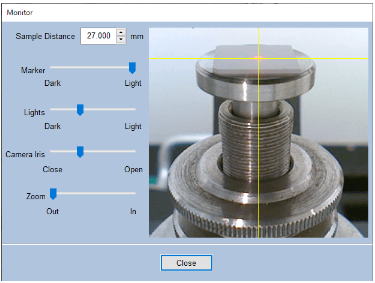

Achieve better, more precise alignment with Pulstec’s optional microscope.

The X-ray spot size can be changed by replacing the collimator. We offer collimators with X-ray spot diameters of 0.8mm and 0.4mm.

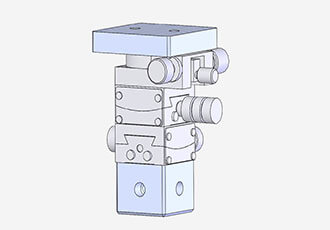

We offer various stage options (3-axis to 6-axis) for the m-Laue with multiple sizes to fit your needs.

The m-Laue’s X-ray sensor can be mounted on the tripod for on-site measurements. The sample size is flexible when using the tripod.

Note: When using the tripod, you must create a safety area or use shielding.

Pulstec offers three shield box sizes:

All options have zero radiation leakage.

If your systems need a sensor to measure crystal orientation, you can combine the m-Laue X-ray device with your machine using our specialized system integration bracket.

We know our technology is leading the industry. Allow us to show you the benefits of working with Pulstec. Contact us today for a free demonstration on-line or at your facility.