Flexible for Large Samples & Integrated Systems

m-Laue Flexible Single Crystal Orientation System

Flexible for Large Samples & Integrated Systems

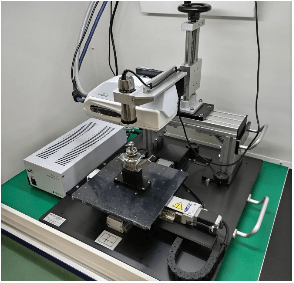

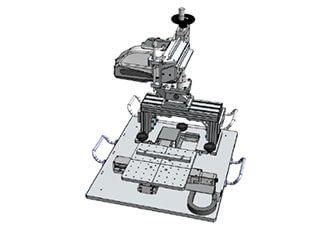

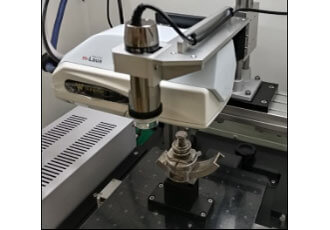

Pulstec’s inline single crystal orientation can be configured for on-site and lab use. Similar to our original s-Laue model, the m-Laue is intuitive. It only takes three simple steps to determine single crystal orientation:

Note: External stage (θ,χ,ψ, and z) is required; shielding plan is required

With the motorized XY slide stage, you can perform orientation mapping within a 150 x 150mm area.

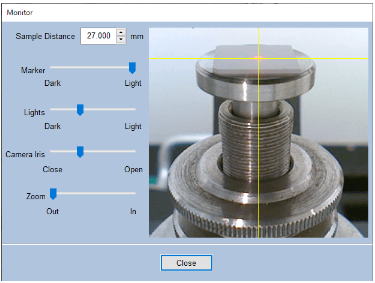

Achieve better, more precise alignment with Pulstec’s optional microscope.

The X-ray spot size can be changed by replacing the collimator. We offer collimators with X-ray spot diameters of 0.8mm and 0.4mm.

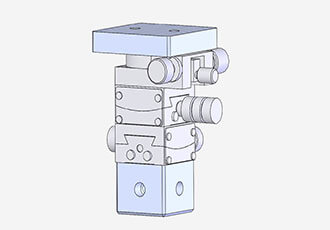

We offer various stage options (3-axis to 6-axis) for the m-Laue with multiple sizes to fit your needs.

The m-Laue’s X-ray sensor can be mounted on the tripod for on-site measurements. The sample size is flexible when using the tripod.

Note: When using the tripod, you must create a safety area or use shielding.

Pulstec offers three shield box sizes:

All options have zero radiation leakage.

If your systems need a sensor to measure crystal orientation, you can combine the m-Laue X-ray device with your machine using our specialized system integration bracket.

At Pulstec, we believe in transparency. Before you purchase a product, we’ll ensure it’s the solution you need. Request your free demonstration today.