A new and improved way to measure residual stress.

μ-X360J Portable X-ray Residual Stress Analyzer

A new and improved way to measure residual stress.

Residual stress and retained austenite measurement is now easier! With the cosα equipment, work that used to take a long time becomes faster, and because of its simple usage, it can be used not only in R&D but also in Quality Control departments. It can also be used for on-site measurement using a tripod, and for automatic measurement systems using robots and 3D scanner.

We offer free sample testing. First five spots for free.

The safety cabinet with interlock is designed to protect users from X-ray exposure. The leakage is less than 0.01 mRem/hour.

The arm is fixed to the specimen with the magnetic stand and can be adjusted finely by 50 mm in both X and Y axes with a micrometer.

Taking your equipment on the go can be a breeze. Our stress analyzer can be packed in a hand-carry case that makes traveling easier.

This is used when you want to measure the internal stress of a sample. It can be used to remove the surface without adding new stress.

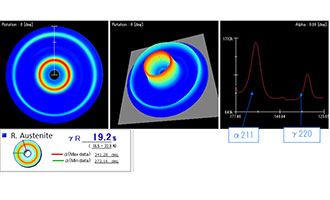

With this added software function, the two-dimensional detector can take the full ring of both martensite and austenite diffraction, and calculate the percentage of austenite which was not transformed to martensite upon quenching.

With this software option, the measurement results obtained using the motorized XY stage can be displayed as color mapping.

By oscillating the angle of the X-ray, diffraction from more numbers of crystal planes are obtained.

The X-ray tube can be replaced by the user. Cr, V, Cu, Co, Mn tube is available.

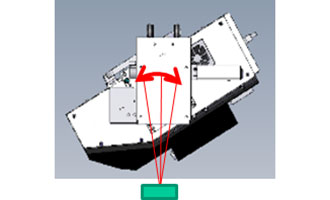

Brochure for the Robotic Residual Stress Measuring System With 3D Scanner

Learn MoreWe know our technology is leading the industry. Allow us to show you the benefits of working with Pulstec. Contact us today for a free demonstration on-line or at your facility.