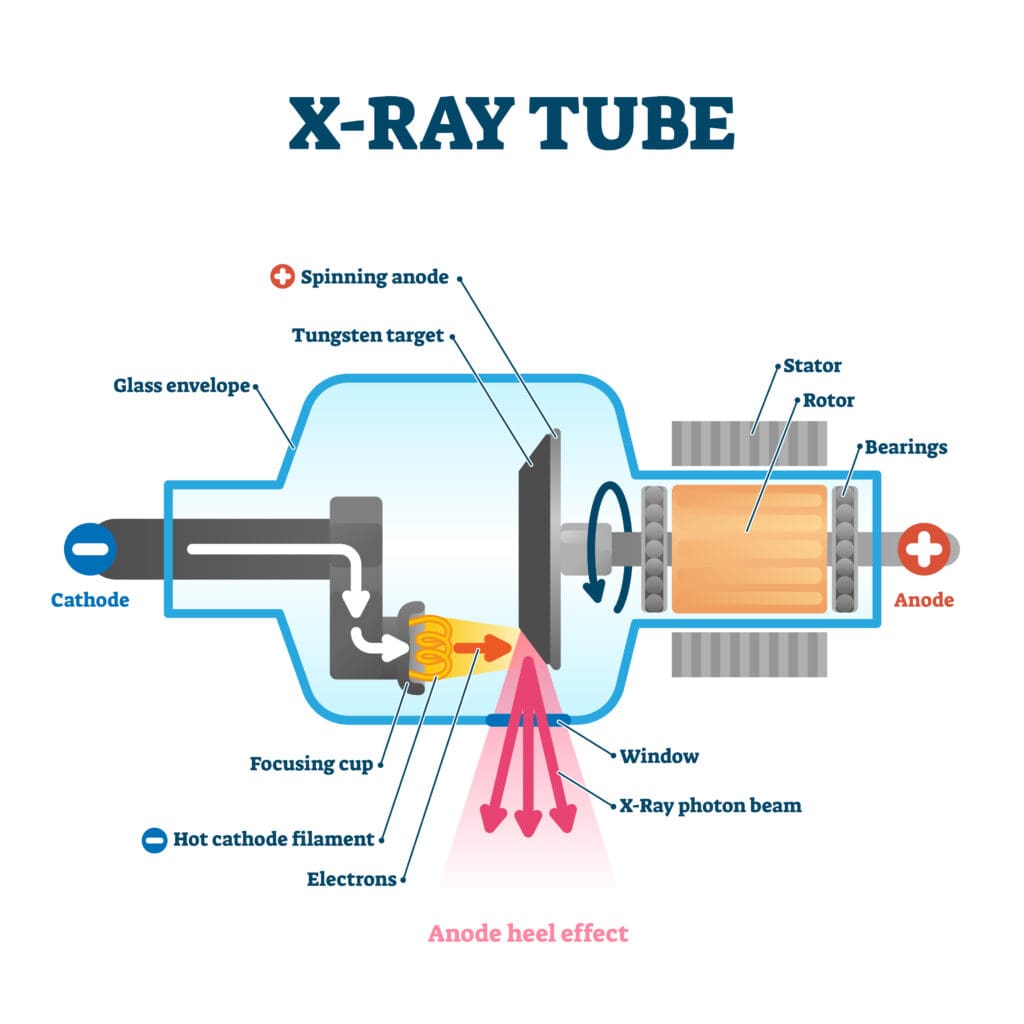

X-ray irradiation is a process where objects are exposed to X-rays. High-energy photons are produced during this process when accelerated electrons collide with a metal target. This collision forces the electrons to decelerate and change direction, releasing energy in the form of X-rays.

In the upcoming sections, we’ll look at how this powerful technology is used throughout many industries, including medical and food safety.

Table of Contents

Irradiation Versus Radiation

Before we cover the purpose of X-ray irradiation and how it’s used, it’s important that you first understand the difference between radiation and irradiation, which are sometimes used synonymously.

Think of radiation as an energy emission from a source, whether from a warm surface or an atomic nucleus. Radiation travels through space as waves or particles and doesn’t require a transfer medium or contact to transfer energy.

Comparatively, irradiation is the process of exposing any object to radiation. It’s also important to understand that even though an irradiated object has interacted with radiation, it does not mean that object has become radioactive.

Now, let’s look into the many industrial purposes of X-ray irradiation and some of its benefits.

The Purpose of X-ray Irradiation

X-ray irradiation is a significant leap in technological innovation that has many industrial purposes, including:

- Medical Devices & Pharmaceuticals: Sterility is critical in medical and pharma applications to prevent harmful microbial contamination in the health care sector as a whole. Fortunately, X-ray irradiation can efficiently sterilize medical devices and pharmaceutical products.

- Analytic in Manufacturing: Both R&D and quality assurance, analytic is a main field in X-ray irradiation. Analytical techniques such as X-ray diffraction(XRD) can measure important characteristics of products: Residual stress, Phase identification and Crystal orientation.

- Food Preservation: Approved food items, such as meat, poultry, and ground meat, can undergo irradiation to eliminate pathogens and increase food safety.

- Pest Control: It may seem unconventional, but irradiation can induce insect sterility to control specific pest populations.

- Imaging: The most recognized application of X-ray irradiation is CT(Computed Tomography) in medical and industrial purposes, which offers an inside view of the objects without the need for invasive procedures. At airports, X-ray baggage scanners are used at security checkpoints to help passengers safe.

Benefits

- Controlled Exposure: A distinct benefit of X-ray irradiation is the ability to control exposure. The capability of electronic devices to switch between on and off states makes it easy to manipulate exposure durations.

- High Penetration Depth: An important factor in industrial applications is having the ability to scan/reach a specific depth. X-ray irradiation is known for its extraordinary penetration depth, making it ideal for in-depth treatment or alteration of materials.

- Fast Processing Times: In manufacturing, time efficiency plays a significant role. X-ray irradiation can help ensure swift processing times, saving valuable production hours.

- Material Compatibility: Another significant benefit is the material compatibility that X-ray irradiation offers. It works seamlessly with a wide variety of materials, resulting in extensive use across industries.

- Focused Radiation: The ability to direct and focus radiation beams where desired offers a greater degree of precision and effectiveness. This not only helps ensure accurate outcomes but also minimizes unwanted exposure to adjacent areas that shouldn’t be irradiated.

- Adjustable Dose Rates: Because most X-ray machines have customizable settings, manufacturers can control the dose rate according to the unique requirements of each project.

Learn More from Pulstec

Founded in 1969, Pulstec is a world-renowned manufacturer known for moving the needle of innovation in the realm of X-ray equipment. We offer a wide range of systems that can effectively and efficiently measure crystal orientation, residual stress, surface hardness, and retained austenite.

Visit our blog for more resources and technical insights, or contact us today to learn more about our X-ray equipment.