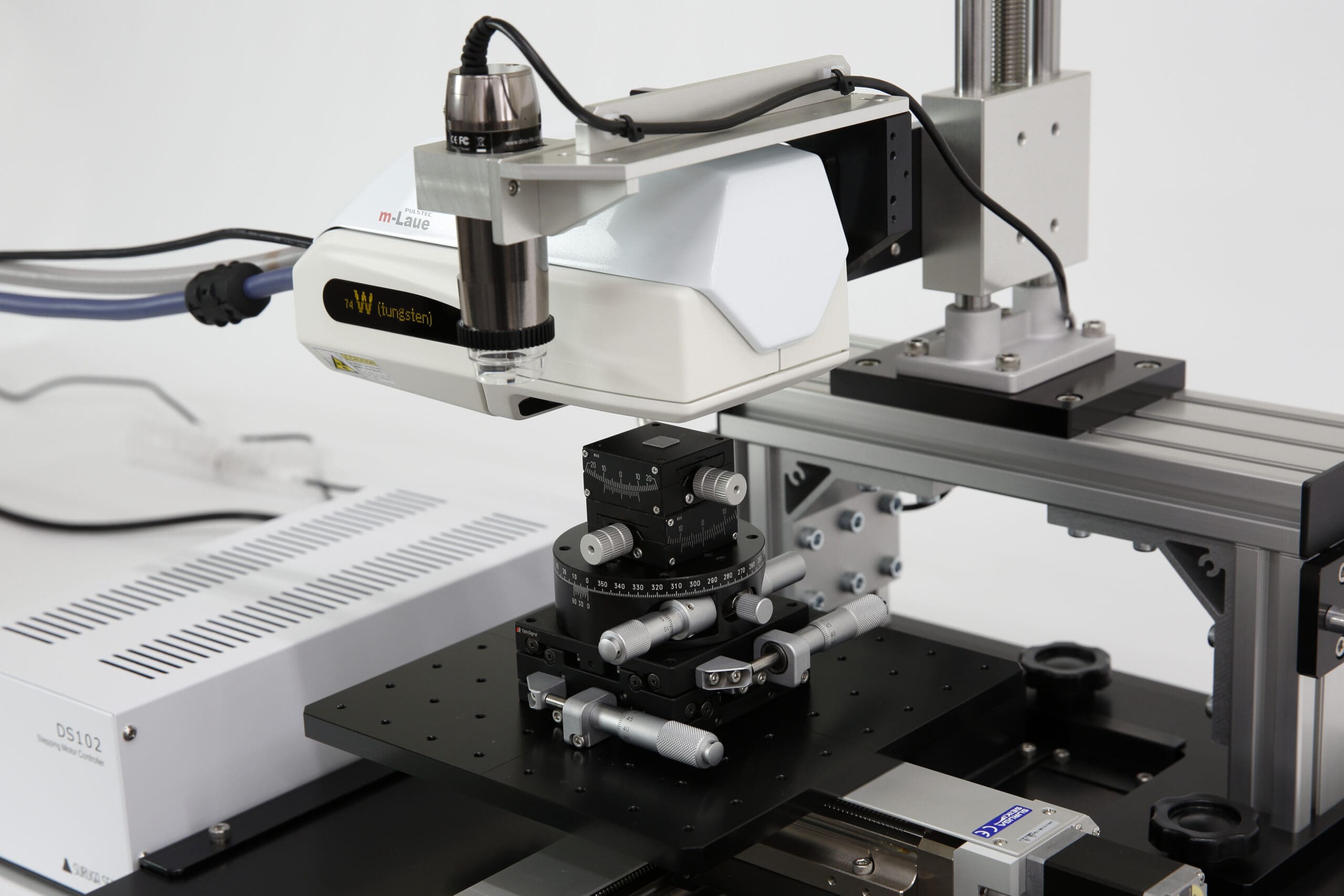

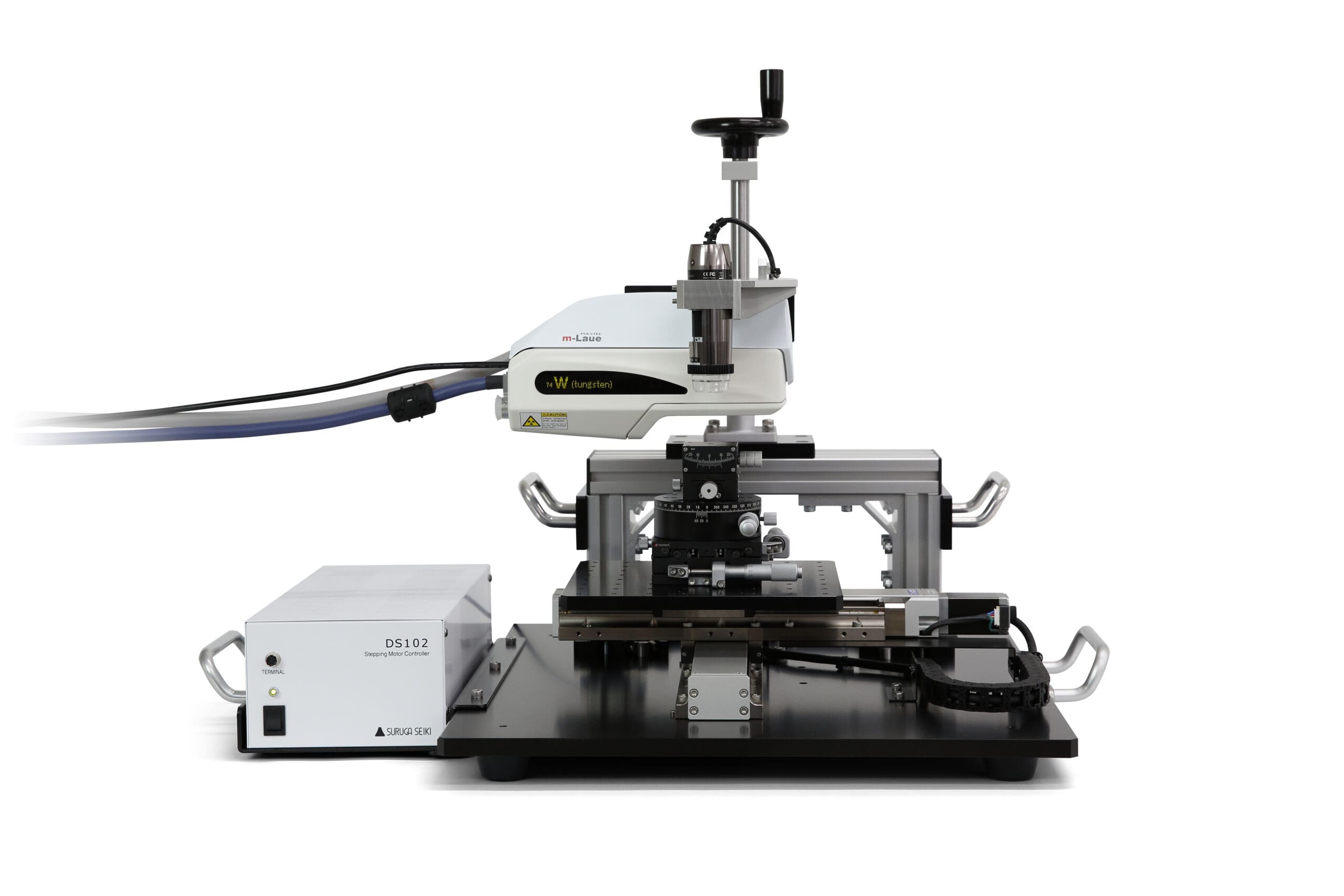

Pulstec’s m-Laue single crystal orientation system is designed to integrate into industrial machinery to carry out verification and quality control processes of critical applications. The unit comes with a proprietary integration bracket that is custom-designed based on the manufacturing machine on which the m-Laue is being installed.

We’ve engineered the m-Laue to integrate seamlessly into ion implantation equipment, wafer grinders, and crystal grinders and cutters.

Ion Implantation Equipment

When integrated into ion implantation equipment, the m-Laue helps:

- Improve channeling control by aligning the crystal lattice relative to the ion beam.

- Provide quick and precise feedback as the wafer is being scanned or rotated, helping to maintain consistent implantation conditions.

- Reduce defect formation, preserve crystal quality, and reduce the need for extensive annealing processes.

- Eliminate the need for separate orientation measurements or manual adjustments for faster processing and less reworking.

Wafer Grinders

Knowing the precise crystal orientation during grinding operations is critical as it helps guide optimal grinding directions. When the m-Laue integrates with wafer grinders, it can:

- Provide information that helps the grinder understand which adjustments are needed as related to the feed rate, spindle speed, and selected grinding wheel to prevent microcracks and other subsurface damage.

- Aid the grinder in compensating for variations in crystal hardness and grinding resistance across different orientations on the wafer surface.

- Help the system detect and compensate for any wafer misalignment or orientation drift during grinding.

- Ensure better surface quality control during grinding.

Crystal Grinders & Crystal Cutters

The m-Laue helps identify the natural cleavage planes within a crystal structure, and when integrated with crystal grinders or cutters, helps them maintain alignment along preferred fracture directions to produce cleaner cuts, improve processing time, and extend operating life.

Integrating the m-Laue with crystal grinders and cutters further helps by:

- Allowing quick feedback to help the equipment automatically adjust cutting speeds, feed rates, and tooling selection to prevent unwanted fracturing.

- Providing precise control that helps grinders and cutters minimize kerf loss.

How the Integration Works

Pulstec offers a proprietary system integration bracket that is custom-designed based on the machine on which the m-Laue is being installed, so the integration process will vary depending on the machinery and application needs.

Some of the most common configurations we’ve engineered include a simple mechanical configuration, where the bracket attaches to the m-Laue and the entire unit is then mounted on the equipment; a bi-directional motorized tilt configuration, which allows for more precise positioning via software; and a slide stage configuration for sampling multiple locations across the crystal surface simultaneously.

Have Questions? Contact Pulstec Today!

Pulstec is committed to helping manufacturers improve process efficiency, accuracy, and speed through our innovative line of X-ray equipment. Please visit our website to learn more about the m-Laue or contact us today to request a free demo or sample measurement.