Achieving consistent case hardness levels requires careful process control and a precise and repeatable measurement technique. If there is even a little variability in the measurement technology, it can lead to less predictable product wear resistance, which is likely to have consequences for the product’s failure after in-service.

Other challenges in measuring case depth hardness are that many of the long-standing technologies are destructive and can take up to 45 minutes to yield useful results.

The good news is that newer methods exist that are non-destructive and much faster without compromising accuracy.

Traditional Methods

Microhardness Testing

Microhardness testing involves applying a light force over a very small area. The process is only intended for thin materials, films, and plated coatings.

The two established microhardness methods are Vickers and Knoop. Both involve pushing a hard pyramid-shaped object into the surface under a known load, holding it there for a fixed time, and measuring the indentation that results. Vickers requires a minimum case depth of 60 μm (0.002”), while Knoop will work on thinner depths.

Both methods require a smooth, polished surface, which takes time to produce.

Rockwell Hardness

In the Rockwell Hardness method, a diamond-shaped indenter is pressed into the sample’s surface under a high load. The depth of the indentation is measured and converted to a Rockwell scale. Rockwell hardness testing isn’t suitable for all applications requiring case depth hardness measurement because it leaves a small mark in the sample being measured.

Brinell Hardness

The Brinell Hardness test is similar to the Rockwell method, except that the indenter has a hemispherical shape. After being pushed into and released from the surface, the diameter of the circle formed is measured. Again, this is unsuitable for some case depth hardness applications because it is destructive.

Specialized Techniques

Leeb Rebound

This hardness testing method entails dropping a ball onto a surface from a known height and measuring its velocity in each direction. The change in velocity can be correlated to the case hardness of the surface.

This non-destructive technique is performed with small, portable equipment, so it is suitable for use on large items not readily transported to a lab. However, accuracy is low as the method is strongly influenced by surface cleanliness, roughness, and material composition.

XRD

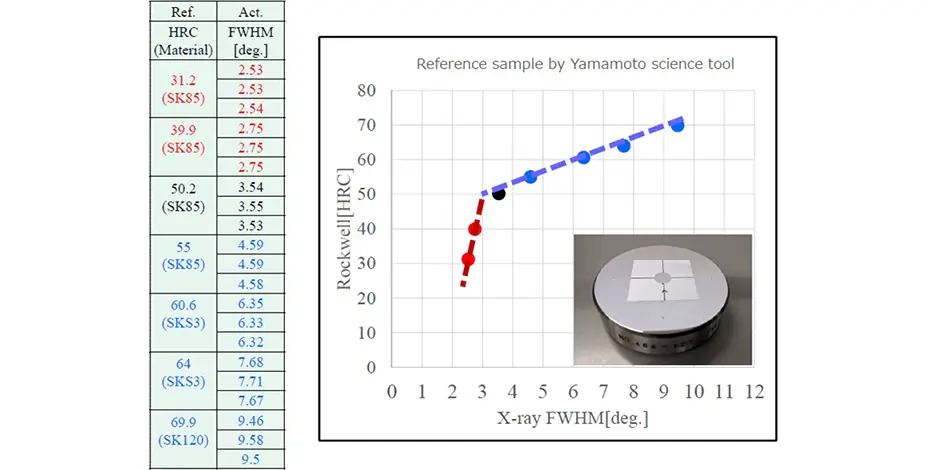

The X-ray diffraction (XRD) method directs a beam of X-rays into the sample’s surface and captures the scattered pattern, known as the Debye-Scherrer ring, that is diffracted from the surface.

Diffraction results from disorganization within the surface atoms and is not a direct indicator of hardness. However, there is a strong correlation between the Full Width at Half Maximum (FWHM) of the Debye-Scherrer ring and the local hardness.

Although the XRD method can only penetrate more than a few microns, it’s ideal for quickly analyzing the outermost layers of a surface without destroying the sample.

Ultrasonic

Ultrasonic testing, sometimes known as Ultrasonic Contact Impedance (UCI), is a variation of the Vickers method.

In UCI, a small indenter on the end of a rod is pushed against the surface to be measured. Ultrasound excites the rod, and its vibration frequency is influenced by the local material hardness. Measuring this frequency gives an indication of local case hardness.

While non-destructive, UCI is sensitive to variations in the material and the surface. It also requires calibration using an alternative hardness measurement technique.

Eddy Current

Case-hardening modifies the conductivity and permeability of the material, which can be detected by eddy current measurement equipment. Rather than providing a hardness value, eddy current provides an indication of case depth.

Eddy current is fast and non-destructive but requires careful calibration for material grades and heat treatment conditions. Accuracy is lower on rough surfaces, and the probe must maintain consistent contact with the surface being measured.

Choosing a Method

With so many available methods, how do you determine which one is best for your application? The starting point is to look at the product or sample, the depth of case-hardening required, and the reason the information is needed. For example, are you trying to confirm that the surface has been hardened, or do you want to measure the thickness of the harder layer?

You’ll also need to consider case thickness, part geometry, required accuracy, and the importance of preservation.

Learn More About Pulstec’s Hardness EYE

Founded in 1969, Pulstec is a leading manufacturer of X-ray equipment, including our Hardness EYE case depth tester, which was developed for accuracy, speed, and ease of use for heat treatment verification, process optimization, and failure analysis applications. Hardness EYE uses XRD to provide precise, repeatable measurements in just a few minutes, requires no pre-processing, such as resin embedding or mirror surface polishing, and comes with an easy calibration feature for every steel grade.

If you’re curious about the Hardness EYE and how it could help with your application, contact us today to request a free demo or sample measurement, or visit our blog for more resources.