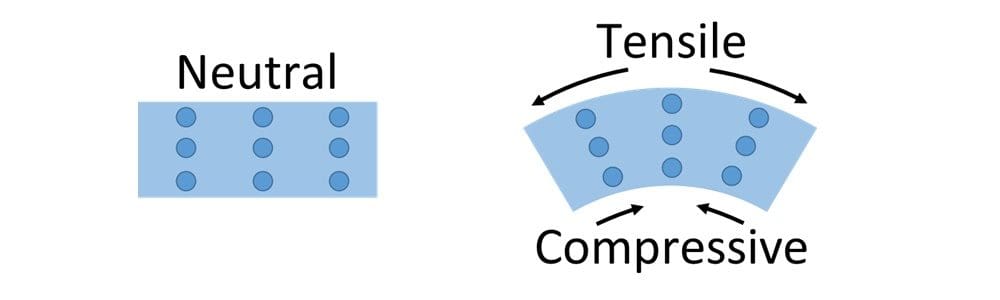

Residual stress is an incredibly important measurement in manufacturing. Due to the deformation of material caused by machining, heat treatments, shot peening, and sanding/grinding processes, residual stresses can be “locked-in” to the material, which could be detrimental to its operating cycles and service life depending on the application.

Generally, there are two categories of residual stress measurement methods: destructive and non-destructive. Destructive measurements can be split up further into mechanical and chemical methods, while non-destructive measurements can include diffraction, ultrasonic, and magnetic techniques.

In this article, we’re going to explore several residual stress analysis methods, including hole drilling, neutron diffraction, x-ray diffraction (XRD), photoelastic stress analysis and Barkhausen noise analysis.

Table of Contents

Hole Drilling

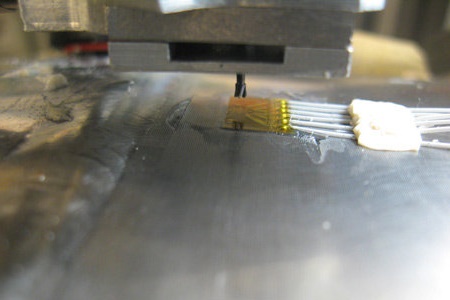

Hole drilling is a destructive residual stress measurement method that can measure macroscopic stresses that are near the material’s surface. A small hole is drilled into the material, causing the stresses within the object to reach a new equilibrium.

Based on how the material around the drilled hole deforms and based on the volume of material that was removed, this deformation can be measured using optical methods or strain gauge.

For more information, SINT Technology.

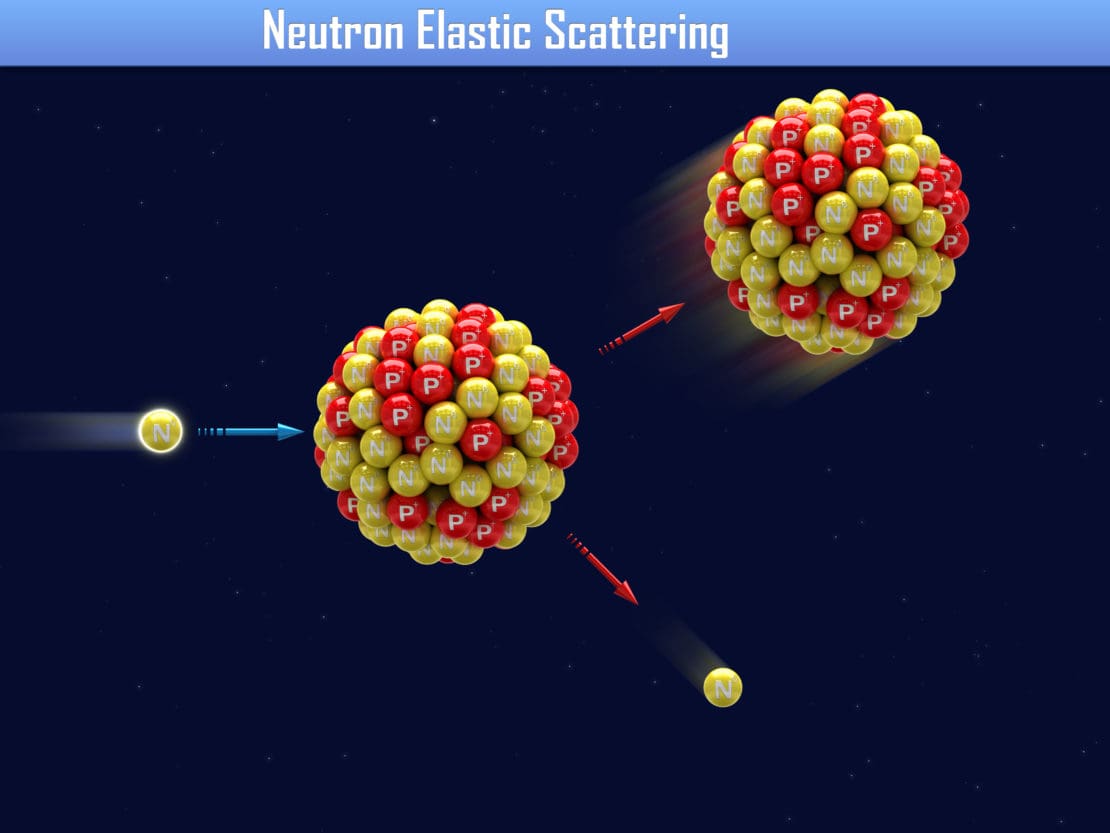

Neutron Diffraction

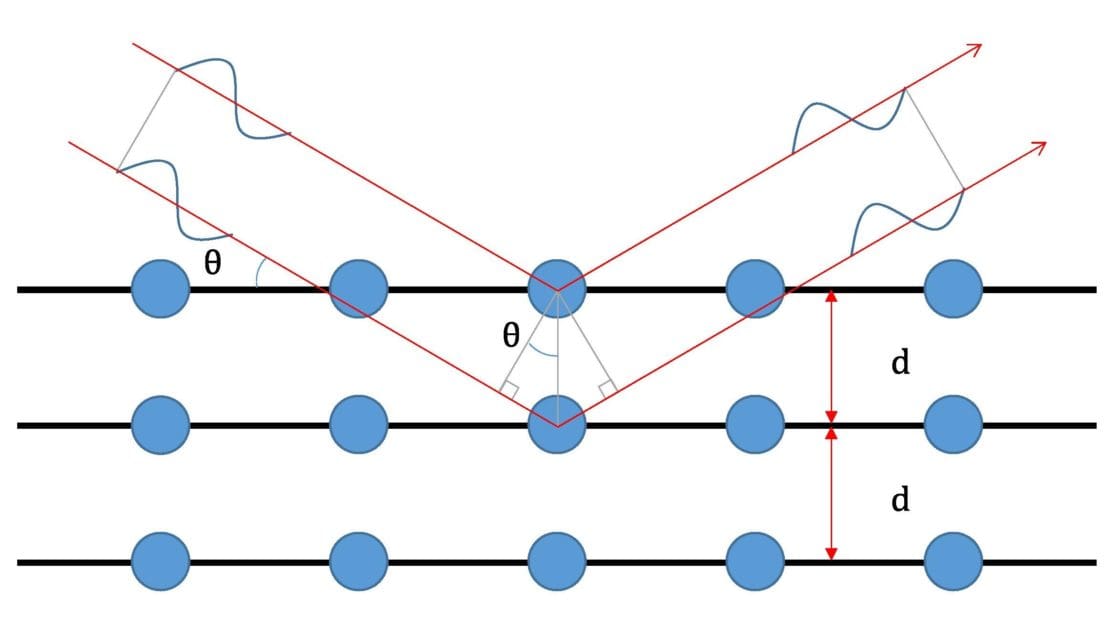

The first type of non-destructive measurement technique is neutron diffraction. In this method, a beam of neutrons is pointed towards the material being measured, and then the diffracted beam is measured. Based on Bragg’s Law, the diffracted beam allows you to detect any changes within the atomic lattice of the material due to residual stresses. Absolute stress values can be obtained by calibrating the measurement using a stress-free sample of identical material.

X-Ray Diffraction (XRD)

X-ray diffraction (XRD) is another non-destructive residual stress measurement technique that is widely used. When measuring residual stress using XRD, x-rays are pointed toward the material and penetrate some microns. These x-rays are then scattered by the polycrystalline solid, producing constructive interference.

After measuring the angle at which maximum diffraction intensities occur, it is possible to calculate the interplanar spacing of each diffraction plane using Bragg’s Law. If there truly are residual stresses within the sample, the interplanar spacing will be different from an unstressed sample.

Photoelastic Stress Analysis

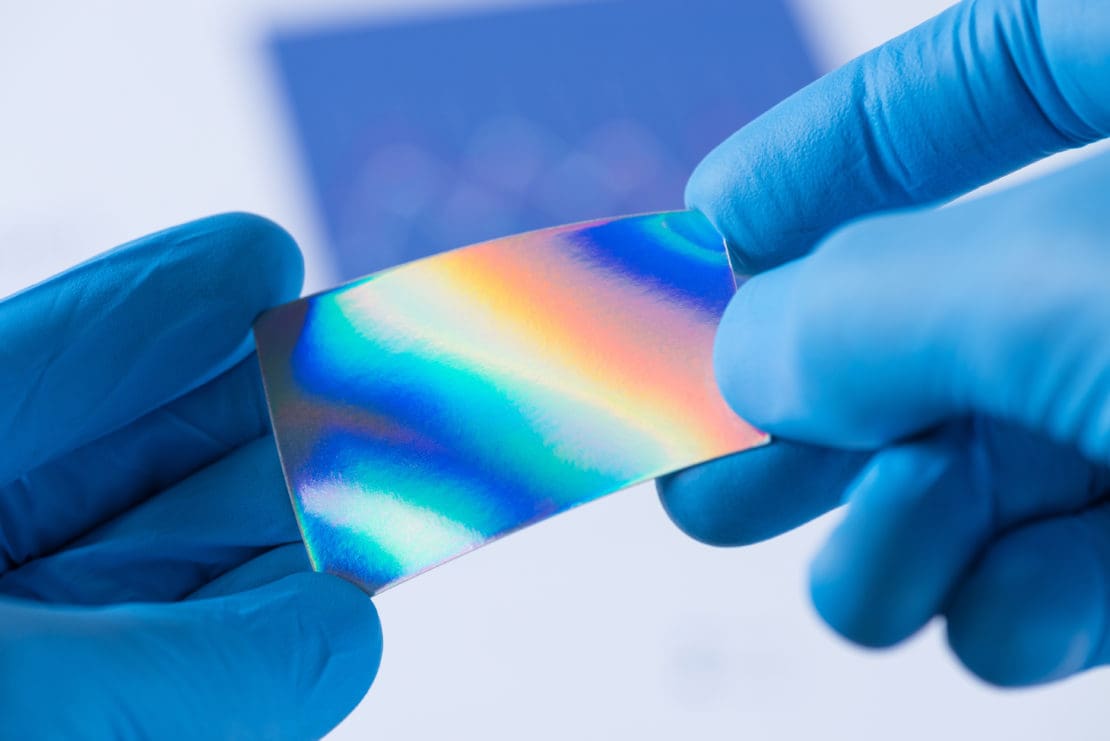

Photoelastic stress analysis is a destructive and qualitative stress measurement method. This measurement is performed by bonding a strain-sensitive plastic coating to the part being measured and then illuminating it with polarized light by using a reflection polariscope. Viewing the object through the polariscope will display strains in a colorful pattern, and allow the operator to identify “strain hotspots” visually.

Barkhausen Noise Analysis

Lastly, Barkhausen noise analysis is a non-destructive stress measurement method. To measure residual stress in this method, a magnetic field is used to induce a noise-like signal within a ferromagnetic material. The limitation of this method is that it only works with ferromagnetic material, and calibration standards are required, but it is both fast and efficient for detecting stresses within ferrous objects.

Which Method Should You Use?

One method can’t cover all your needs, and there is no right or wrong method when it comes to measuring residual stresses. However, a primary decision point should be whether or not you want your material to be damaged during the process.

If your material must stay intact, it’s recommended that you utilize a non-destructive method, like X-ray diffraction, to get a quick, safe measurement. Additionally, if you want a simple setup that doesn’t require an extensive amount of machinery, equipment, or external analysis, diffraction is one of the best measurement methods to go forward with.

Once you’ve considered the type of measurement method you want to use, you should ensure that the material you’re measuring is compatible with that method. Diffraction, for example, is used with polycrystalline materials while photoelastic stress analysis is primarily used with glasses and transparent plastics.

Have Questions? Contact Pulstec Today!

Do you have questions about residual stress measurement? Get in touch with our team at Pulstec! Founded 1969, we’re a leading manufacturer of non-destructive residual stress XRD analyzers. Using the cosα method of XRD, our product is lightweight, portable, easy to set up and configure, and can provide measurements in just 60 seconds!

To learn more about our product, or to request a free sample measurement, please fill out our online form today.