Pulstec is proud to introduce MuraR, the only non-destructive hardness variation analyzer in the world. It’s fast, accurate, and easy to set up.

Table of Contents

How Does the MuraR Work?

The MuraR scans the surface at high speed in combination with XY stage, rotation stage, or robot.

It calibrates the FWHM (full-width half-maximum) obtained from X-ray diffraction and hardness reference specimens.

After calibration, it then maps the obtained FWHM as hardness.

Why Is Our Hardness Variation Analyzer Important?

Unlike etching and Barkhausen noise tests, using our analyzer after heat treatment is not time-consuming. In fact, it can scan a 2 x 2-inch area in just 120 seconds!

Features

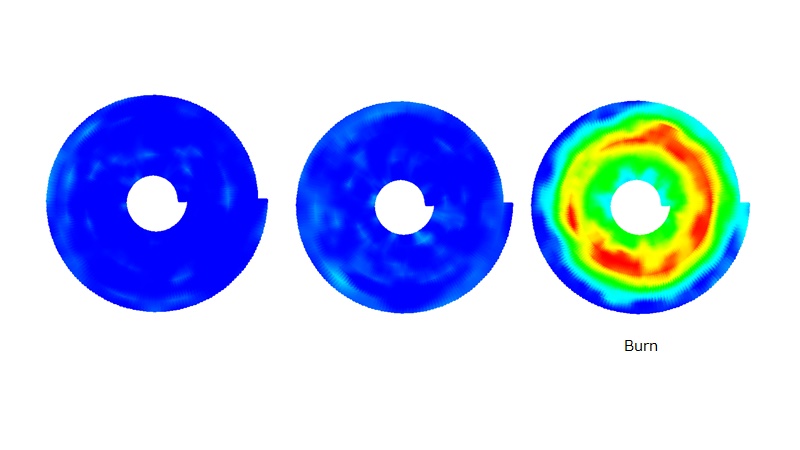

- High-Speed Scanning of Hardness Variation: Our non-destructive analyzer allows you to measure the effects of heat treatment, machining burns, and grinding burns

- Inline Inspection & Robotics Integration Available: The MuraR‘s small size and lightweight sensor head makes inline inspections and robotics integration easier than ever.

- Convenient Automatic Mapping Function: When you customize our software, you can take advantage of our auto mapping function. In this function, you’ll be able to see grind layers.

- No Visual Inspection Needed: With our analyzer, you won’t need to perform any visual inspections, which often require special skills.

Applications of Our Hardness Variation Analyzer

Our non-destructive analyzer is perfect for the following applications:

- Inspection or Evaluation for Machining/Grinding Burn

- Nital Etching Inspections

- Inspection of Quenching Variations After Heat Treatment

- Inspection of Heat-Treated Steel Parts (Bearings, Gears, Chains, CVT, Pulleys, etc.)

Interested in Learning More?

Pulstec USA is proud to at the cutting edge of measurement and scanning technology. Visit our website to learn more about our non-destructive hardness variation analyzer. If you have questions or would like to request a demo, please don’t hesitate to contact us.