Retained austenite refers to austenite that does not transform into martensite after a heat treatment, particularly quenching.

To break it down further, there are two crystal structures of iron: body-centered cubic (BCC) and face-centered cubic (FCC). Iron can reach FCC or BCC phases depending on the temperature it’s heated to. During quenching, when iron and carbon have been heated to a transformation temperature, austenite, an FCC phase, forms. After the steel cools, it may turn into ferrite, which is a BCC (body-centered cubic) phase, or into martensite, a BCT (body-centered tetragonal), which is a deformed BCC lattice.

The amount of austenite that remains as the steel cools depends on the cooling speed, carbon content, and alloy content, but it can comprise as much as 40% of the steel.

In this article, we aim to answer some of the most common questions surrounding retained austenite, including what causes it, its effects, and how to measure it.

Table of Contents

What Causes Retained Austenite?

As previously mentioned, austenite changes to other allotropes of iron like martensite and ferrite as it cools in a process known as martensitic transformation. However, this process is never complete, no matter how cold the steel gets.

Retained austenite will always exist because a small fraction of it remains in a highly stressed state, preventing the phase change from FCC to BCT or BCC. The very process of martensitic transformation causes this stress, making it impossible to completely eliminate it.

What Are the Effects of Retained Austenite in Steel?

Small differences in the amount of retained austenite can dramatically affect the physical properties of steel. Manufacturers measure retained austenite in order to create the right balance for their parts.

In general, retained austenite is neither good nor bad; it entirely depends on the application of the produced part. Let’s take a look at some of its properties.

Fatigue Strength

Two characteristics of austenite can help improve fatigue life. One is ductility of austenite, which can delay crack growth. The second is the increase of compressive residual stress during service. The compressive stress can delay crack growth by closing/clamping existing cracks.

Toughness

Martensite is hard and strong, but brittle. Austenite is soft, but tough, and it has higher impact strength, which can prevent cracking from a sharp blow.

Dimensional Stability

The greatest disadvantage of austenite is in applications that rely on steel’s dimensional stability. The tendency of austenite to transform into martensite or lower bainite means that parts containing high levels of austenite can change their size, even after they cool. This property is particularly problematic when it places the part under stress, causing it to distort and crack.

How Do You Measure Retained Austenite?

You can use optical microscopy to measure large amounts of austenite (15% or more). The most accurate way to measure retained austenite as low as 0.5% is through XRD (x-ray diffraction). Crystalline materials like steel lend themselves well to analysis by XRD. This is because the atoms in these materials are arranged in regular arrays.

Bragg’s Law (nλ =2d sin θ) determines the suitability of a material for XRD. In Bragg’s Law, n is the diffraction order, λ is the wavelength of the X-rays, d is the interplanar spacing between successive layers of atoms, and θ is the angle of diffraction.

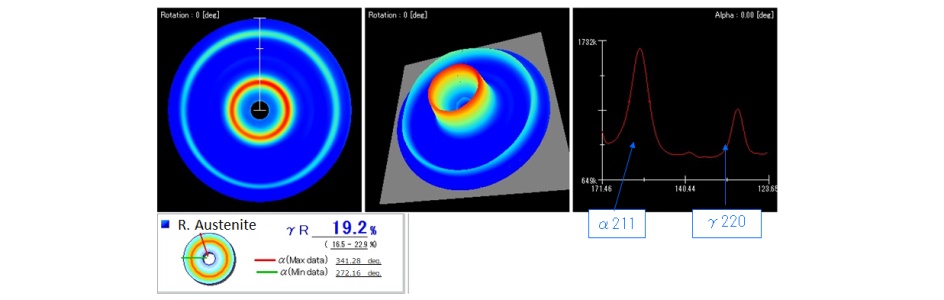

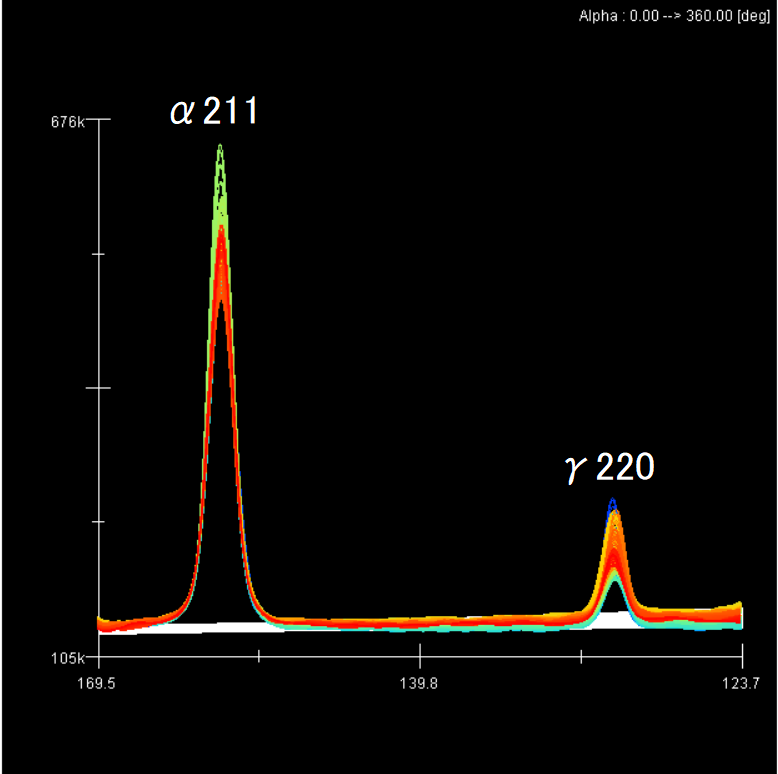

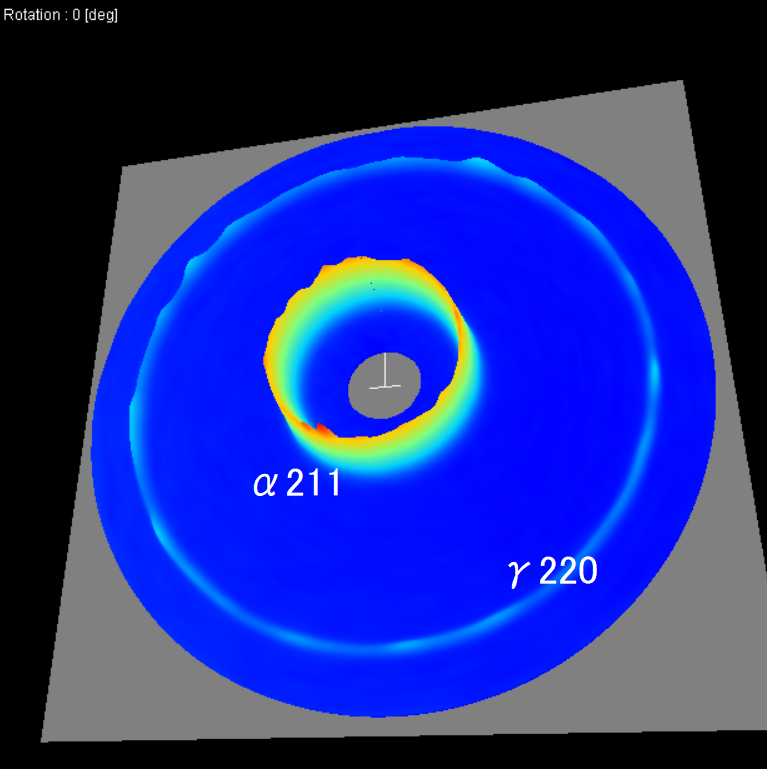

The X-ray hits the sample and diffraction occurs according to Bragg’s Law. The integrated intensity of the martensite diffraction (211) and the austenite diffraction (220) are taken, and the ratio of volume fraction is calculated.

Retained Austenite Measurement: Zero- & One-Dimensional Sensors Vs. Two-Dimensional Sensors

Zero- or one-dimensional sensor equipment, such as Sin2𝜓-based equipment used to be the most common method of measuring retained austenite. With Sin2𝜓 equipment, the sensor is tilted during X-ray exposure to detect the diffraction from the austenite and martensite phase, which is time consuming.

Two-dimensional sensor equipment, such as cos𝛼-based equipment, is a newer technology with many benefits. This type of equipment is fast, easy to set up, and easy to operate. It records two complete Debye-Scherrer rings from the austenite and martensite phase on the two-dimensional sensor without any tilt of the sensors, which can save time. Furthermore, it’s more accurate when compared to zero- or one-dimensional sensor equipment. This is because all information from the Debye-Scherrer ring is used, which removes any outside influence from variations in grain texture.

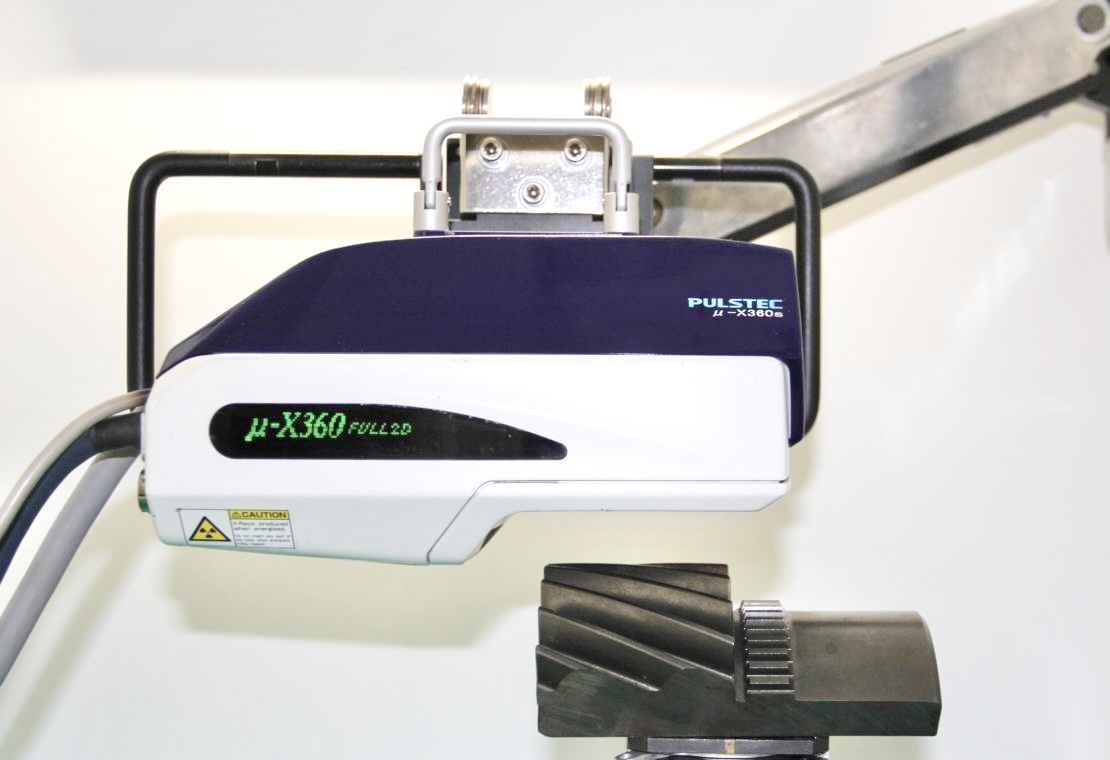

Learn More About Pulstec’s Retained Austenite Measurement Device Today

If you have questions regarding retained austenite, or want to learn more about our analyzers work, please contact us today for a free demo and consultation.

Pulstec USA researches, develops, and produces residual stress and retained austenite measurement devices using the cos𝛼 method of X-ray diffraction. We’re also proud to be the developer of the world’s first non-contact surface hardness variation scanner.